Cutting techniques

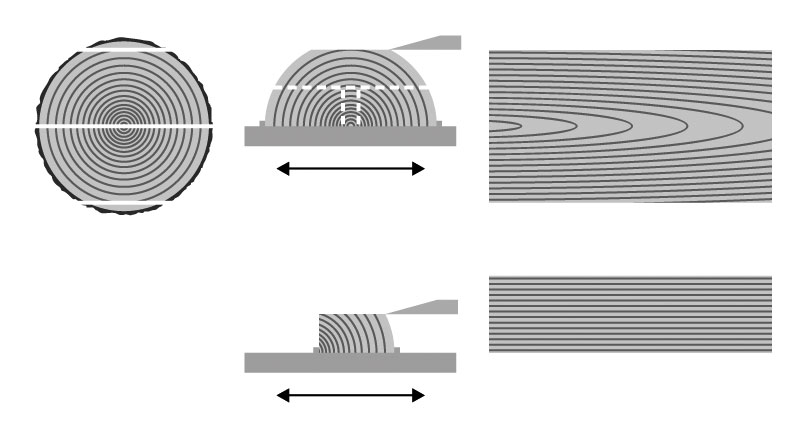

Flat slicing:

Cutting technique: halved log, sliced from the outside

Veneer figure: When slicing flat, the veneer sheets on the outside of the trunk show a vivid grain pattern because the vegetation zones (annual rings) are cut at a very flat angle. The closer the cut is to the core of the trunk, the more the annual rings are cut at right angles. The veneers show an increasingly stripy structure.

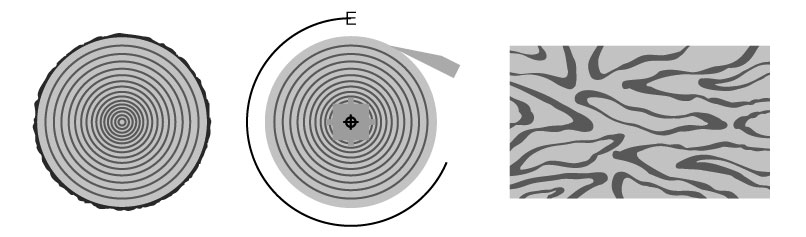

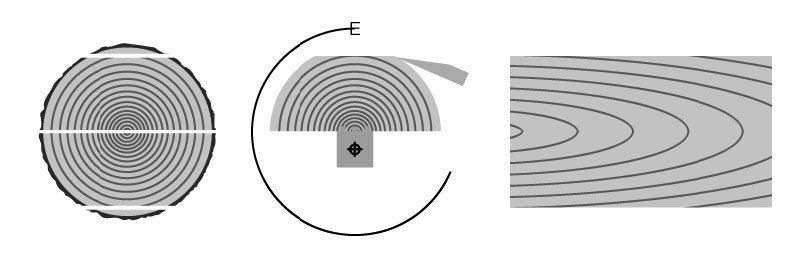

Eccentric and stay-log peeling:

These production techniques produce veneer patterns similar to those produced by slicing.

Peeling technique: During stay-log peeling half-block is eccentrically clamped on rotating beams; peeled very flat by annual rings.

Veneer texture: Stripy on the side, floral texture inside.