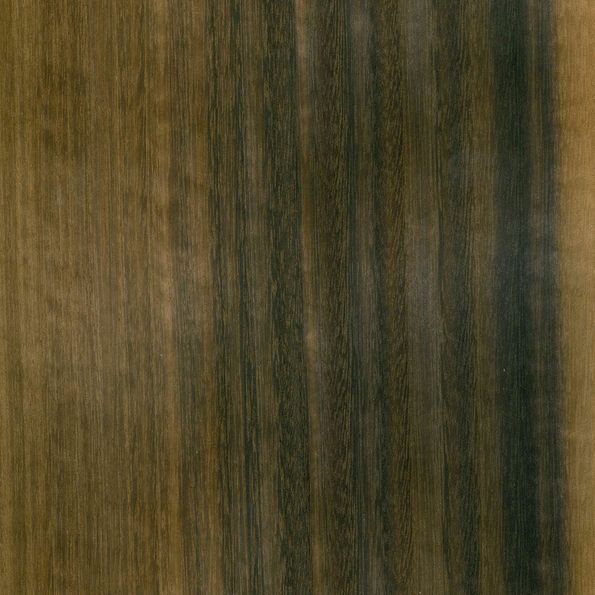

Natural play of colors

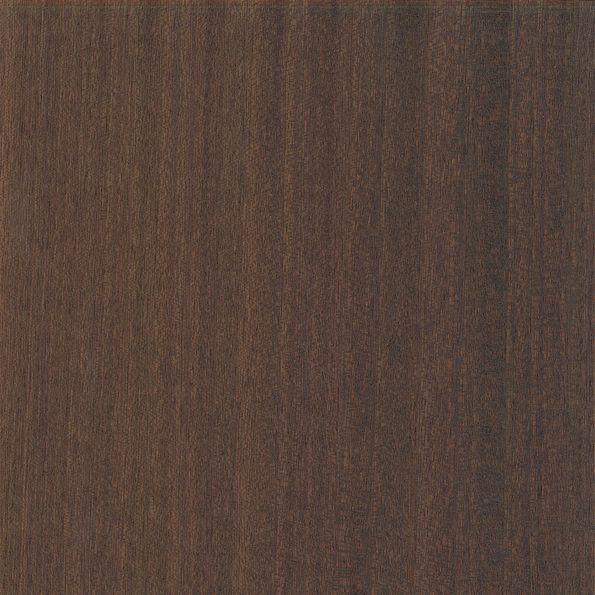

In order to equalize color differences and achieve a hazelnut to deep chocolate brown surface color with an elegant, natural shine, woods were already smoked in the Middle Ages. The technique fell somewhat into oblivion in recent years, because dark woods were not very popular. When smoking, the different tannic acid contents in the wood cause slight tinting variations with unique light and shadow effects. If the wood is not completely kerned, light sapwood zones remain visible even after smoking. These are characteristic of European Oak, for example, and give the smoked Oak an unmistakable natural identity.

Smoking with modern technology

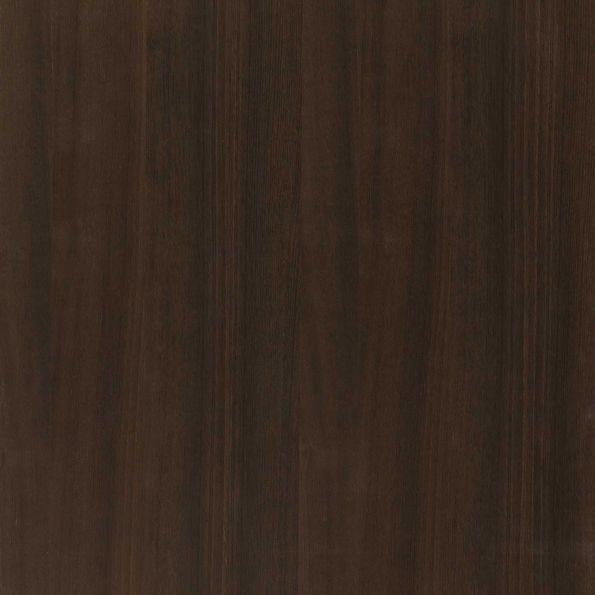

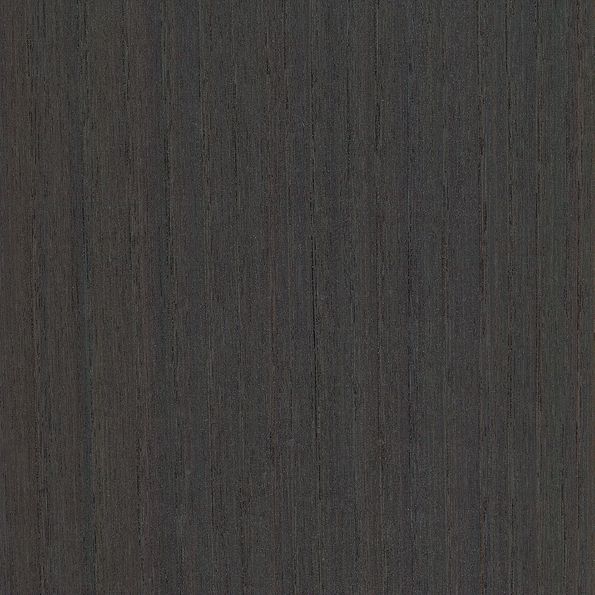

The smoking of woods such as Oak, Acacia or Larch causes a coloration of the surface after a short treatment by the action of ammonia (NH3) and a complete coloration of the woods after a longer period of time. In contrast to many other natural or colored woods, the color is largely resistant to aging and light. The smoking process also modifies the wood, making it more elastic, less brittle and thus easier to work and process.

With the predominantly native smoked woods a completely new color palette is available. You will find all Roser smoked veneers in our Veneer Library.

FAQs Smoked Veneer

Smoked veneer is created by treating woods like oak, acacia, or larch with ammonia vapors. This process changes the wood's color from honey brown to deep black, making it more flexible and less brittle.

Smoked veneer gives furniture and interiors an elegant look. The dark tones are age- and light-stable, meaning the furniture will retain its beauty over time.

For smoked veneer, domestic woods such as oak, acacia, and larch are preferred. These woods contain enough tannins, which are essential for the color change during the smoking process.

The color tones created by the smoking process are age- and light-stable. This means that the furniture will retain its dark color even when exposed to direct sunlight.

No, smoked wood does not emit harmful substances. After the smoking process, the wood is completely safe to use.

After cutting, the veneer sheets should be allowed to air out for 3-4 hours to remove any remaining ammonia residues. This ensures clean joint gluing.

For smoked veneer, it is recommended to treat it with oil or wax. The veneer should not be sanded as this could affect the depth of the color.

Roser AG offers smoked veneer in its veneer library. Interested parties can inquire about the products directly on the website or arrange a consultation at the concept room in Birsfelden.

The color palette ranges from honey brown to deep black. The exact shade depends on the type of wood and the duration of the smoking process.

Yes, smoked veneer is ideal for furniture making and interior design. The modified woods are stable, durable, and give furniture an elegant appearance.

Downloads (only available in German)

Links

Reference Grand Hotel Les Trois Rois

Reference Raiffeisenbank Dornach

Smoked Veneer in our Veneer Library

Contact

+41 61 367 40 60