Veneer at its Finest – From Our Own Production at Roser

Buy Veneer Directly from the Manufacturer – With Quality, Traceability and Experience

Are you searching for veneer from the manufacturer, real wood veneer, custom veneer solutions, or Swiss-quality veneers? Then Roser AG is your ideal partner. For over 110 years, we have been selecting the best logs across Europe – with a trained eye and deep understanding of wood quality. In our in-house production, we transform these logs into premium veneers for high-end interior fittings, quality furniture, and sophisticated doors.

Our commitment: Every veneer sheet is a unique piece.

As one of the few companies in Switzerland with its own veneer production, we handle every step from log selection to the final veneer in-house. This guarantees consistently high quality and allows us to respond flexibly and individually to your requirements. Whether curly maple, European walnut, oak or elm – we offer a wide range of wood species and can accommodate special requests.

Our strengths at a glance:

- In-house veneer production on a contract basis

- Personal log procurement across Europe

- Decades of experience and numerous reference projects

- Sustainable and transparent sourcing (PEFC/FSC available)

- Individual consultation in our concept.room

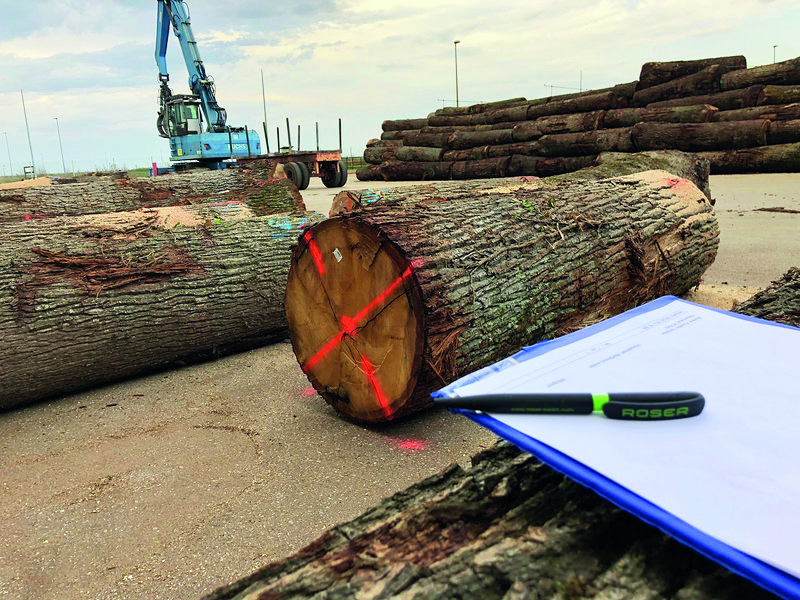

Log purchasing in the forest

At Roser, veneer production begins with a personal step: our experts go into the forest themselves to carefully select each tree. The suitable trunks are labelled directly on site with special markings that guarantee a clear classification in the further process. In this way, we ensure that exactly the wood that meets our quality standards is processed. Depending on the location, the subsequent transport to the veneer factory is carried out in an environmentally friendly manner by rail, ship or lorry.

Storage in the veneer plant

After arriving at the veneer factory, the logs are carefully stored until further processing. To protect them from drying out and undesirable changes, they are stacked tightly between so-called polters and kept moist by continuous irrigation. Especially in the warmer months, this method is crucial to prevent the development of so-called "shrinkage" - dark discolouration on the end faces that can later become clearly visible in the veneer. Such visual defects considerably reduce the value of the wood, as it is then no longer suitable for high-quality veneers. This protection is particularly essential for light-coloured wood species such as maple, birch or beech, as flawless, shrinkage-free lengths are often required. For woods with a particularly high value, the end grain is also sealed with paraffin to retain moisture for longer and slow down the drying process. Nevertheless, the time window for processing remains limited - for this reason, many veneer manufacturers prefer to produce sensitive hardwoods in the colder months if possible in order to minimise quality losses.

Log preparation in the veneer plant

Before a log is transferred to the actual veneer production process, it is first prepared. In this step, the log is carefully inspected and assessed - a task that requires in-depth expertise and a great deal of experience. Based on the individual characteristics of the wood, a decision is made on which cutting technique to use, which lengths are appropriate and where the log should be optimally cut. Each log is unique - an incorrectly selected cut or an unsuitable processing method can significantly reduce the potential of even a high-quality log and drastically reduce its value.

A precise assessment at this early stage is therefore decisive for the later quality of the veneer and its possible areas of application - be it as a fine veneer for doors, furniture or wall panelling. The key assessment criteria include the course of the wood growth, the diameter, the straightness of the trunk and internal features such as the heart crack. Large trunks are particularly impressive. They offer the greatest possible flexibility in subsequent processing and are treated with corresponding care.

In the next phase, the machine processing of the logs to produce veneer begins. Firstly, the log is cut to the desired length - this process is called cross-cutting. Each section produced in this way is precisely measured and labelled with an individual factory number. This number accompanies the wood through the entire production process and enables complete traceability back to the place of origin in the forest. At the same time, the measured volume number forms the basis for subsequent invoicing to the customer, for example when calculating the slicing fee.

After cutting to length, the wood is debarked. Depending on the desired result, the log is then halved, quartered or cut into thirds on a log bandsaw - the resulting pieces are called flitches. This preparation is crucial for the subsequent veneer appearance. An exception is the round peeling process, as used for rotary cut veneer: here the log remains whole and is removed in a spiral. See also veneer processing.

Boiling or steaming the logs

In the next processing step, the logs and log sections are placed in large steel water basins where they are boiled or steamed. This process fulfils two key purposes: on the one hand, it makes the wood softer and more elastic, which is crucial for a clean, high-quality cut when slicing. On the other hand, it also has a significant influence on the colouring of many types of wood. Beech, for example, has a very light, almost whitish colour in its natural state, but only develops its characteristic, slightly brownish tone through intensive steaming.

The temperature, duration and intensity of steaming are customised depending on the type of wood. This can range from a few hours - if the aim is simply to improve workability - to treatments lasting several days in order to achieve the desired colour effects. These so-called steaming pits are therefore a central element for the subsequent veneer quality.

Planing in front of the cutting machine

After the steaming process, the prepared logs are transported to the block planing machine, where their supporting surfaces are planed exactly flat. This step is crucial to ensure stable and even support on the vertical slicing table - the so-called support table - during the subsequent slicing process. Only a precisely machined surface enables clean, continuous veneer sheets of high quality.

At the same time, planing fulfils an important protective function for the sensitive blade: The so-called "cleaning" removes the last residues such as grains of sand, small stones or deposited dirt, which could otherwise damage the blade's cutting edge or lead to premature wear. This processing step is therefore not only of great importance for the quality of the veneer, but also for the longevity of the machine - a classic example of the interplay between craftsmanship and technology in veneer production.

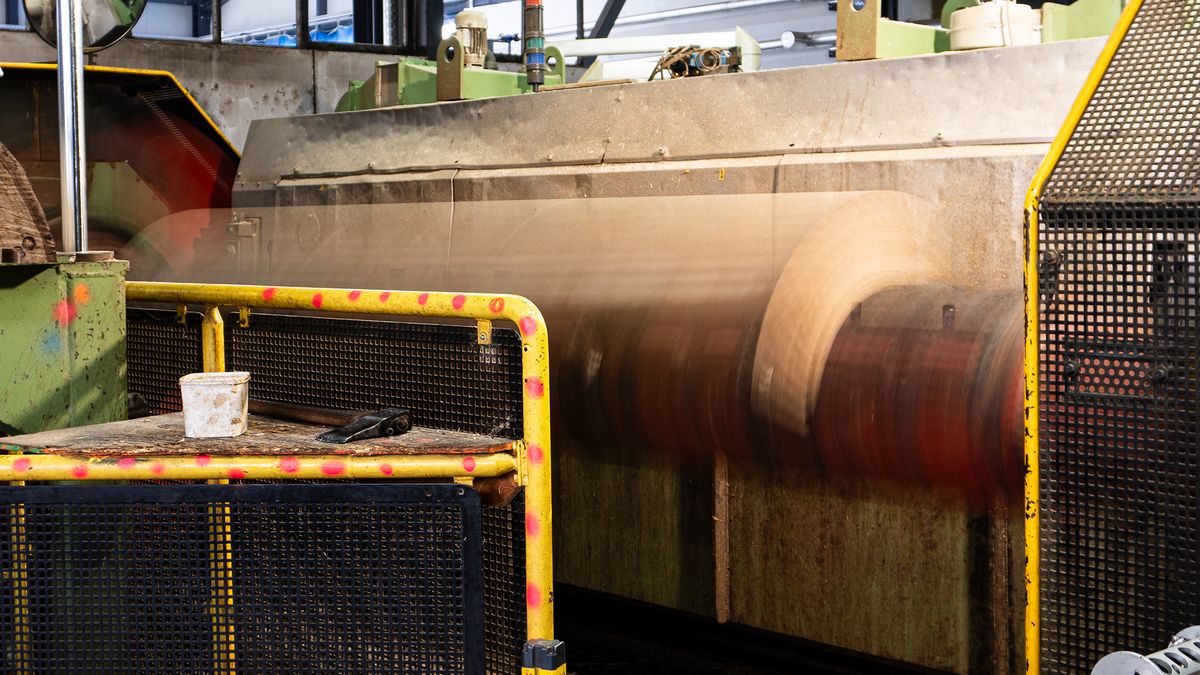

Veneer slicing

After preparation, the cut block parts are transported to the peeling or slicing machine, where they are processed into veneer using various methods depending on the desired look and application. Both types of machine work with a precisely harmonised unit consisting of a knife and pressure beam. The blade separates the veneer sheet from the log layer by layer, while the pressure beam compresses the wood immediately before cutting. This compression is essential to produce a clean cut and minimise cracking in the veneer.

The precise adjustment of the distance between the blade and the pressure beam determines the veneer thickness - usually with a tolerance of just 0.1 mm. Without the necessary pressure from the beam, the veneer would tear badly, making it unusable for many applications. Nevertheless, fine surface cracks on the side facing the knife - so-called micro-cracks - can never be completely avoided.

Veneer cutting

After preparation, the block parts are clamped in a vertical slicing machine. Here, the knife table moves up and down with the wood, while the knife and pressure beam are fixed. During the outward stroke, the pressure beam presses the wood together to the exact preset veneer thickness - typically with an accuracy of 0.1 mm. Each upward stroke separates a veneer sheet from the log, and despite machine performance of up to 120 cuts per minute, this maximum speed is rarely achieved in practice.

There are different methods depending on the cutting technique and the desired veneer pattern (see also slicing techniques):

- Flat slicing (most common method): The log halves - especially for quarter flat cutting - are clamped with the core side facing the knife table. This is usually done with so-called claws, which grip the top and bottom of the log. This creates a lively feathering ("flower") - the veneer strips become more streaky from the core.

- True quarter measurement: Here, each quarter is clamped and cut at right angles to the direction of growth. This results in a continuous striped pattern throughout the veneer.

- Faux quartering: The processing is similar to flat cutting, but initially produces a semi-floral pattern that becomes more striped towards the core.

Historically, these log sections were fixed by claws, which inevitably left a knife remnant - an unused piece of wood about 18 mm thick. In the past, this was mostly waste, but today it is coveted as a decorative piece. Modern machines now predominantly work with vacuum fixing - this reduces the knife remnant to approx. 3 mm, which means considerable material savings, especially in annual production - extrapolated to around 4,000 logs per year, this is a noticeable difference.

Slicing rotary cut veneer

In the production of rotary cut veneer, the logs are sent to the peeling machine, where veneer sheets are produced by rotating the block. There are three main processes (see also slicing techniques):

1. rotary or full-round peeling (rotary peeling)

The log is clamped axially and rotates all round against a stationary knife. This creates a continuous, endless band of veneer - ideal for extracting as much surface area as possible from the log. The resulting pattern appears irregular and wild, but gains aesthetic value with grained wood species such as bird's eye maple

2. stay-log or half-round peeling (eccentric / stay-log peeling)

Here, one half of the log is clamped with the core side on the so-called stay-log. The eccentric rotation creates a veneer with a combination of a floral centre and striped edge - visually close to the flat cut, but with a higher material yield, particularly suitable for smaller logs or wood species with a lower demand for striped patterns.

3. rift or rift peeling

The log is quartered and clamped with one flat side facing outwards. The knife peels eccentrically, resulting in a continuous striped veneer pattern, similar to the real quartering technique for sliced veneer and particularly popular for high-quality oak veneers

Drying - ironing - pressing

After slicing, the wet veneer sheets are transported to modern mesh belt dryers, which bring them through several temperature zones to a final moisture content of around 8-14%. With accompanying pressure from rollers, any unevenness is "ironed out" to achieve the smoothest possible surface. Despite this smoothing, some sheets may have to be pressed again due to differences in density - a time-consuming but important step. This is the only way to ensure that the veneer industry can process the sheets reliably - without warping, breakage or increased waste.

Trimming - Packaging - Labelling

After drying, the veneer packages are trimmed and packaged. First, the sheets are trimmed to uniform dimensions - edge defects or noticeable irregularities are carefully removed. The cut sheets are typically put together in bundles of 24 or 32 sheets to ensure even stacking.

The parallel trimming of the bundles takes place on the so-called shearing line - here the veneer appearance can be optimised once again and conspicuous blemishes can be specifically cut out (clipping).

The bundles are then electronically measured: photocells or measuring sensors record the width and length. The length is rounded off to whole 5 cm increments as standard; the width is measured at short intervals and the average is precisely documented in full centimetres. In the case of particularly valuable burl veneers, the length is often even specified to the nearest centimetre, as such bundles are usually shorter and require greater precision.

After measurement, each bundle is immediately assigned a barcode label. This label contains important information such as the number of sheets, length, width, master number, consecutive bundle number and the total area in square metres. With the help of appropriate software and scans, each bundle can be clearly identified immediately and assigned to its storage location, quality or sales price - so it is always possible to trace where each bundle is located.

Pricing

After final processing and drying, each veneer package undergoes a sample-based quality inspection. Visual characteristics, moisture behaviour and physical properties are evaluated in a structured grading process. This, together with previous market knowledge, forms the basis for targeted pricing - individually tailored to the format, figuration, growth character and demand. This method ensures that each product is optimally classified, fairly priced and remains traceable from the initiation to the customer history to the final use.

FAQs Veneer production at Roser

Our logs are sourced primarily from sustainably managed forests in Switzerland and Europe – including France, Germany, Croatia, Slovenia, and Italy. We only purchase legally harvested timber with full traceability.

We produce everything ourselves. From selecting the logs to the finished veneer, we control every step – ensuring consistent quality, flexibility, and tailor-made results.

Our standard selection includes oak, curly maple, walnut, ash, beech, elm, and other fine hardwoods. For special projects, we also procure exotic species.

Absolutely. We produce custom veneers tailored to your project, your surface concept, and the required specifications.

Veneer is by nature the most resource-efficient way to use premium wood. Our production follows ecological standards, with full transparency and certified supply chains where needed.

Yes – upon request, our veneer experts will visit you. Whether you're a carpenter, door manufacturer, architect, or private client: we bring veneer samples, assess your needs on site, and offer practical recommendations tailored to your project.

Yes – many well-known clients from Switzerland and nearby countries have been working with our veneers for years. We're happy to show you relevant examples upon request.

After an initial consultation – in our konzept.raum or by phone – we develop a tailored concept. We then select the appropriate logs and produce the veneers. Upon request, we also handle cutting, pressing, or bonding to substrates.

Prices vary depending on wood species, quality, sheet size, and quantity. We will gladly provide a customised, transparent quote based on your specific needs.

Simply reach out by phone, email, or via our contact form. We look forward to hearing from you!