Rotary cut veneers

We offer a comprehensive range of rotary-cut veneers, which are available directly from stock or can be produced to customer specifications if required. Thanks to many years of experience in the field of rotary-cut veneer projects, we guarantee consistently high quality and support individual designs with precisely customised solutions.

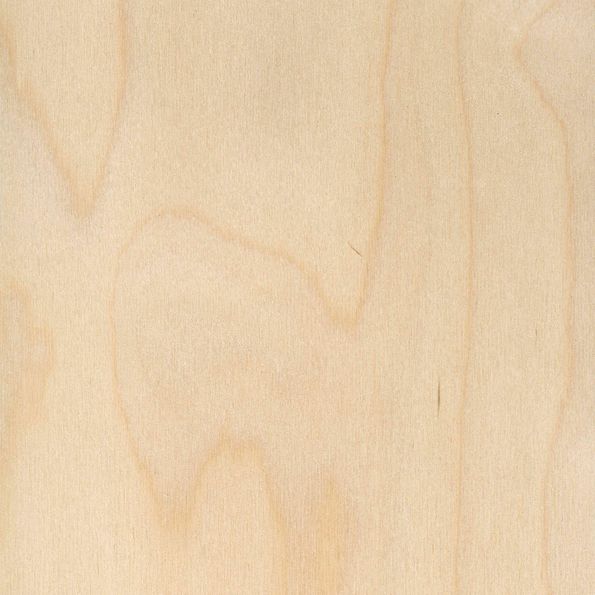

In addition to the tried and tested classics such as bird's eye maple, American maple, birch and various burl woods, we also process maritime pine logs as rotary cut veneer.

The structure of the classic maritime pine plywood panels inspires architects, but the use of these panels in high-quality interior design is very questionable.

There are also limits to the use of plywood panels for fire protection requirements, doors and acoustic applications. Selected maritime pine logs are peeled into 0.8 mm thick veneer. The veneer sheets are joined and assembled to the customer's dimensions and then pressed onto the desired substrate. From chipboard and MDF boards to gypsum-based substrates such as Knauf or Norit, any standard substrate can be covered with maritime pine. Even acoustically effective, micro-perforated panels are no problem. Matching edgeband material can also be produced on request in a wide range of thicknesses and widths. In-house production ensures that even large objects can be realised with a homogeneous appearance.

We have also achieved great results when peeling ash, oak and beech. Contact us for personalised advice.

We also have rotary cut veneers as Veneer Express Layons in our assortment:

FAQs rotary cut veneer

Rotary cut veneer is a type of veneer that is produced by splitting thin layers of wood from a rotating log.

During rotary peeling, the entire log is clamped in the centre axis and peeled off in a spiral from the outside. This results in veneer patterns with irregularly flattened patterns or with nests of wild structures. As the growth rings are cut very flat, rotary cut veneer does not have a natural appearance, but is visually very wild and textured.

This method enables large veneer sheets with particularly even grain patterns.

Rotary cut veneer is characterised by its cost efficiency and uniform surface structure. It is ideal for large-surface applications such as door panels, furniture parts or wall panelling and ensures a uniform appearance.

Rotary cut veneer is ideal for panelling doors, furniture and interior fittings. Thanks to its stability and uniform appearance, it is often used in modern design projects.

Roser AG offers a variety of wood species as rotary cut veneer, including tamo (Japanese ash), thuja burl, chestnut burl, elm burl, maritime pine, quilted maple, American and European maple, birch, bird's eye maple, European and American walnut, madrona, myrtle, birch, elm, poplar, ash, beech and oak.We will be happy to advise you on the right type of wood for your project.

Rotary-cut veneer is particularly resource-efficient, as large quantities of veneer sheets can be obtained from one log.For example, up to 800 square metres of interior quality veneer can be obtained from one pine log. In addition, the wood at Roser AG comes from sustainably managed forests, which guarantees an environmentally friendly choice of material.

In principle, any type of wood can be peeled, but peeled lime, for example, is too plain in appearance and oak looks too spongy on the surface.

Links

Rotary cut veneers in our Veneer Library

Article from Schweizer Schreinerzeitung

Contact

+41 61 367 40 60